Casting Study: Tracing Machine

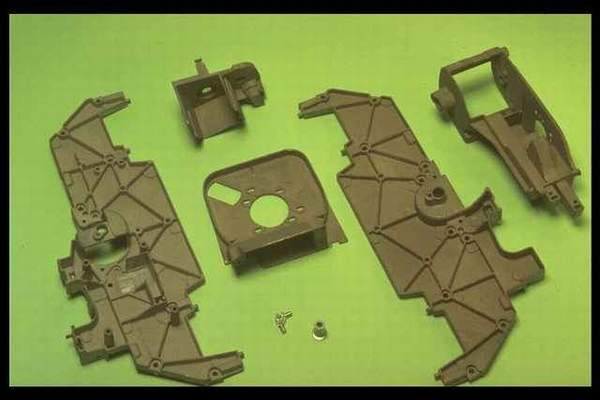

Océ Graphics – one of the world’s leading manufacturers of tracing machines – uses zinc alloy die castings in each of the seven machines in its range. Zinc alloy castings form part of the structure of the machines, through the two side plates and two grips in the paper holder. The motors which drive both the paper movement and the carriage are mounted on zinc die cast supports, and they are linked to the coder by zinc die cast connectors. The movements of the two motors are transmitted by zinc die cast pinions. The motor and drive mechanism for the pen carriage are also in zinc. The carriage itself moves on three assemblies of rollers driven through zinc castings. The choice of zinc alloy pressure die castings for the eleven different parts in these precision machines was made because of the excellent overall performance of the material – good mechanical and physical properties and ready castability into the required precise shapes.

Océ Graphics – one of the world’s leading manufacturers of tracing machines – uses zinc alloy die castings in each of the seven machines in its range. Zinc alloy castings form part of the structure of the machines, through the two side plates and two grips in the paper holder. The motors which drive both the paper movement and the carriage are mounted on zinc die cast supports, and they are linked to the coder by zinc die cast connectors. The movements of the two motors are transmitted by zinc die cast pinions. The motor and drive mechanism for the pen carriage are also in zinc. The carriage itself moves on three assemblies of rollers driven through zinc castings. The choice of zinc alloy pressure die castings for the eleven different parts in these precision machines was made because of the excellent overall performance of the material – good mechanical and physical properties and ready castability into the required precise shapes.