WHAT IS THE ZINC CHALLENGE?

The Zinc Challenge is a competition created for undergraduate industrial design students who are currently enrolled at a College or University in North America. Students are encouraged to submit designs in zinc that meet the functional and aesthetic needs of the product and demonstrate the advantages of zinc alloys and the zinc die casting process.

Three winners were selected, and each participant or group will receive an award for use at the college or university at which they are currently enrolled. A $2,000 award will go to each of the top three winners and $1,000 will be donated to their faculty advisor for use at his or her discretion within the department.

WHAT’S INVOLVED?

1. FILL OUT THE ENTRY FORM

Fill out an entry form for each participating student. Each entry form must be endorsed by a faculty member from the school. Click the icon above to access the form.

2. COMPLETE THE QUESTIONNAIRE

3. SUBMIT DESIGN AND QUESTIONNAIRE BY THE DEADLINE

Submit your unique design along with the completed questionnaire to ZincChallenge@zinc.org by TBD

CONTEST RULES AND FAQ’S

COMPETITION OVERVIEW

The theme of the 2025-2026 Zinc Challenge is TBD

ELIGIBILITY

This competition is open to all undergraduate students enrolled at an engineering or design college or university in North America in the current academic year.

NUMBER OF ENTRIES

Single applicants: Fill in the information requested.

Group applicants: Designate one representative as the applicant, and place this person’s name and contact information in the appropriate sections. The remaining group members must have been listed on the zinc questionnaire and then on the back of the entry form. Limit one entry form per design submission.

ENTRY FORMAT

The design entry must be organized in one (1) adobe .pdf file containing three (3) pages so that the complete concept with development can be understood. The judge should not be required to make any assumptions not clearly shown in the file.

The following layout is suggested but not required:

- Page 1 should detail the challenge and show the design development for the idea,

- Page 2 should make clear the reason why zinc combined with high pressure die casting is appropriate for the manufacture and use of the part,

- Page 3 should show the part isolated and in use for the intended application.

Written text should be minimal but is essential. The entry should select a zinc alloy appropriate for the design and describe why the solution is effective. Include a parts list and any text needed to highlight unique features that may not be clear unless identified.

.

A review of past winning entries [below] may be beneficial for understanding the requirements.

SUBMITTING YOUR DESIGN

- Complete the electronic entry form.

- Submit both the design and questionnaire by TBD to: ZincChallenge@zinc.org.

- The body of the email must contain the name of the student, the school and supervising faculty member.

AWARDS

JUDGING CRITERIA

ANNOUNCEMENT OF RESULTS

JURORS

TERMS & CONDITIONS

CONGRATULATION TO THE WINNERS!

ZINC CHALLENGE: 2024-2025

Furniture Hardware

Please note that winners are listed in no particular order

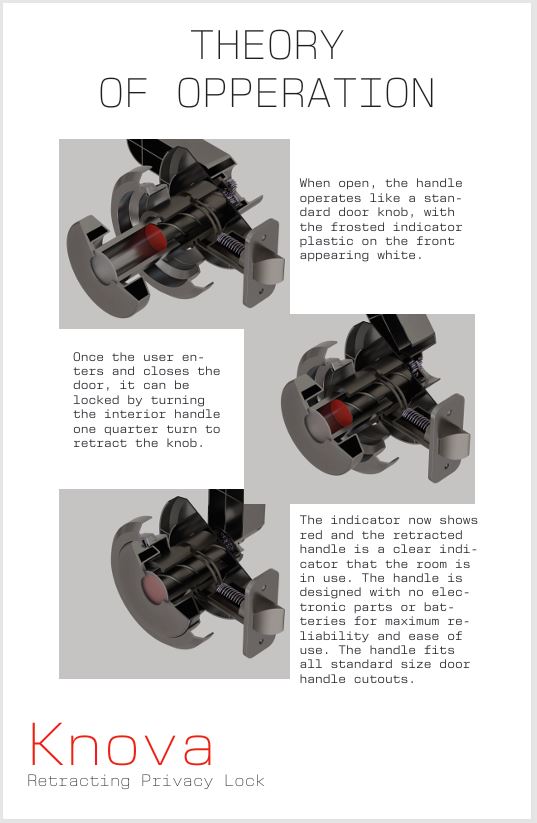

Title: Knova

Designer: Alex Gross

School: University of Oregon

Instructor: Kiersten Muenchinger

Judges’ Comments:

- Multifunctional retracting knob indicates room occupancy manually.

- Good justification for die casting and Zamak 3 alloy selection.

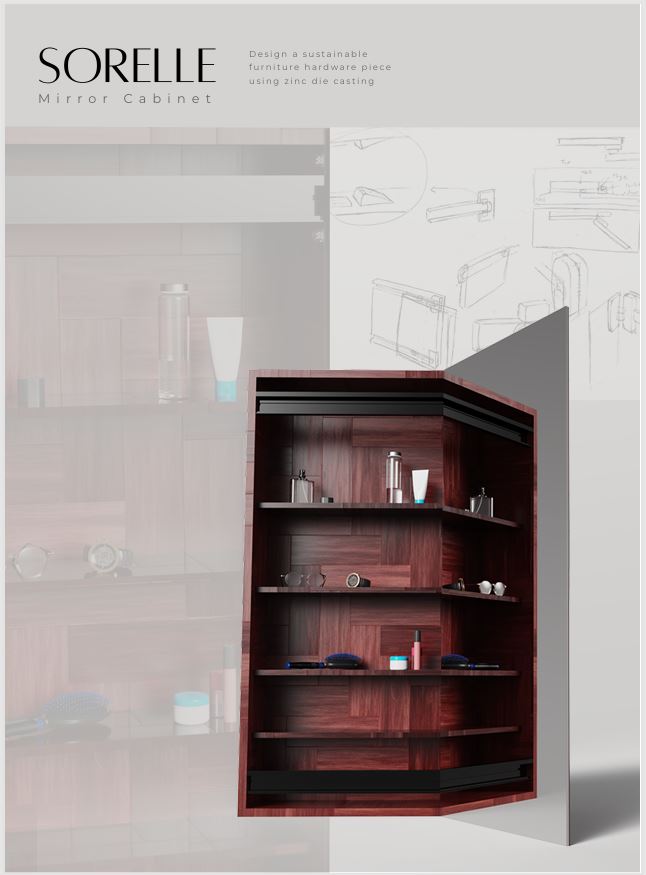

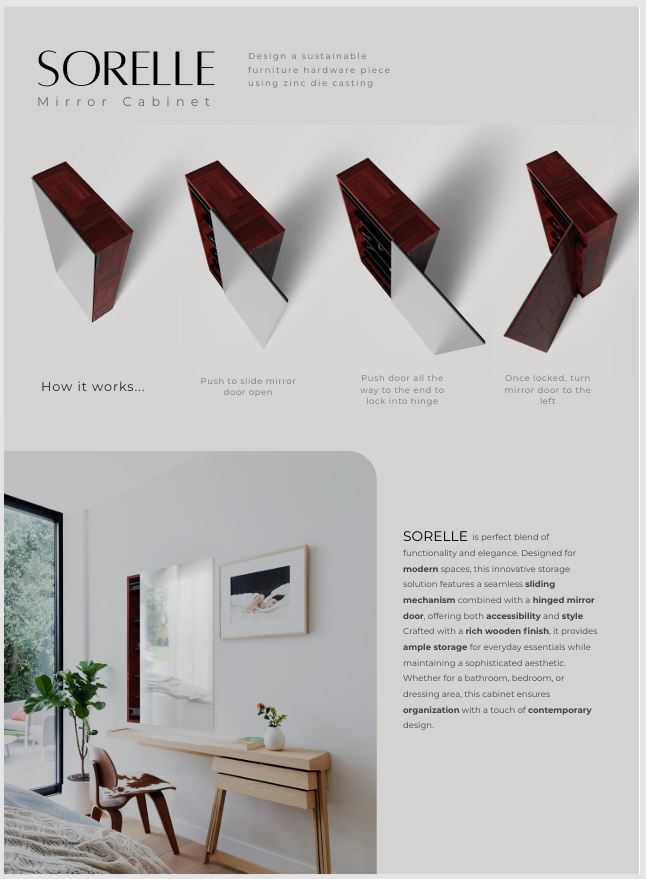

Title: Sorelle

Designer: Jessica Wong

School: Purdue University

Instructor: Steve Visser

Judges’ Comments:

- Creative use of hinges and rail system for innovative design functionality.

- Excellent awareness of properties to specify ZA-8 and Zamak 5 in the design.

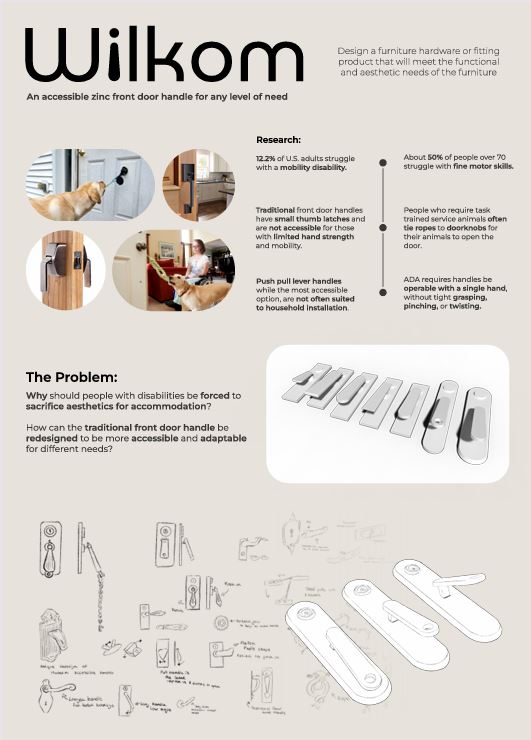

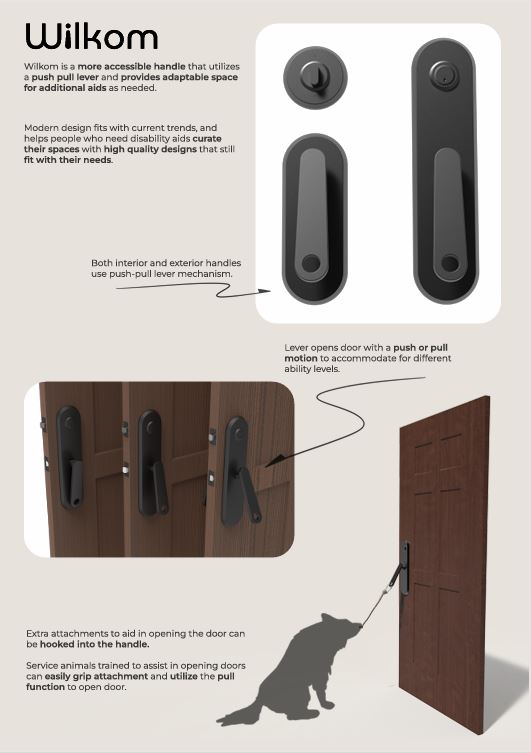

Title: Wilkom

Designer: Bronte Marie Kunkler

School: Purdue University

Instructor: Abolfazl Ghaderi

Judges’ Comments:

- Great response to a well researched and documented design need.

- Fantastic design for zinc die casting with large market potential.

ZINC CHALLENGE: 2023-2024

Sustainable Beauty Products

Please note that winners are listed in no particular order

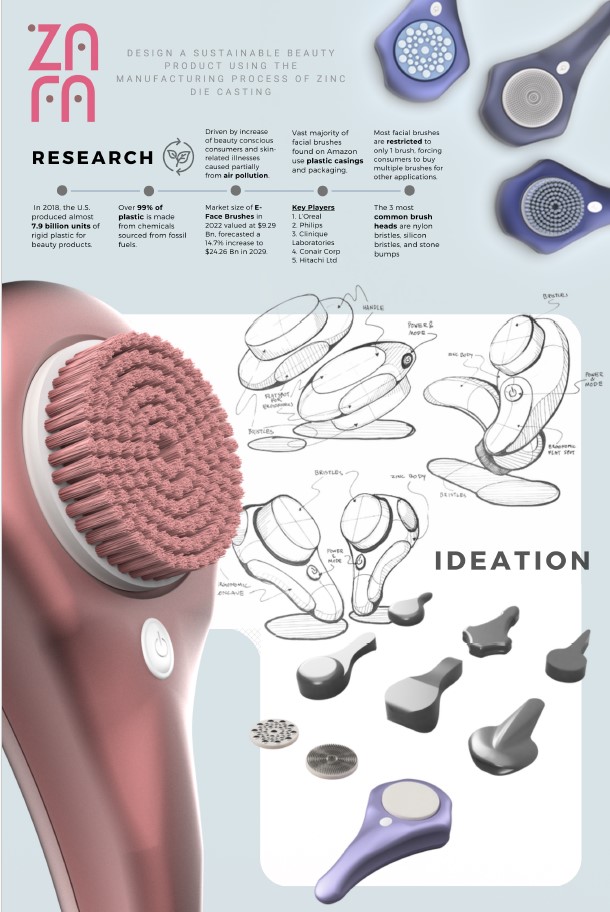

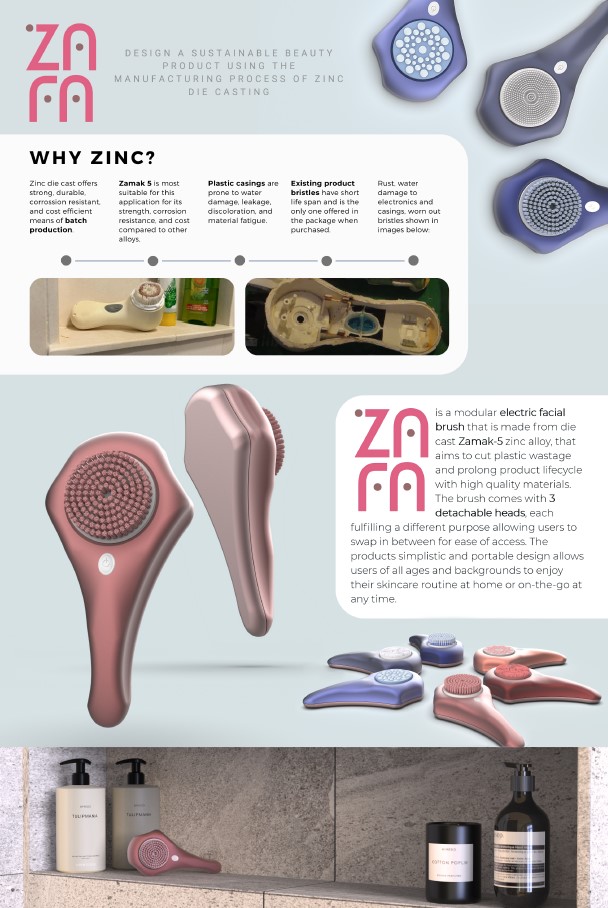

Title: ZaFa facial brush

Designer: Alexander Yuhin Ho

School: Purdue University

Instructor: Steve Visser

Judges’ Comments:

- “Color options add glamor to an everyday product”

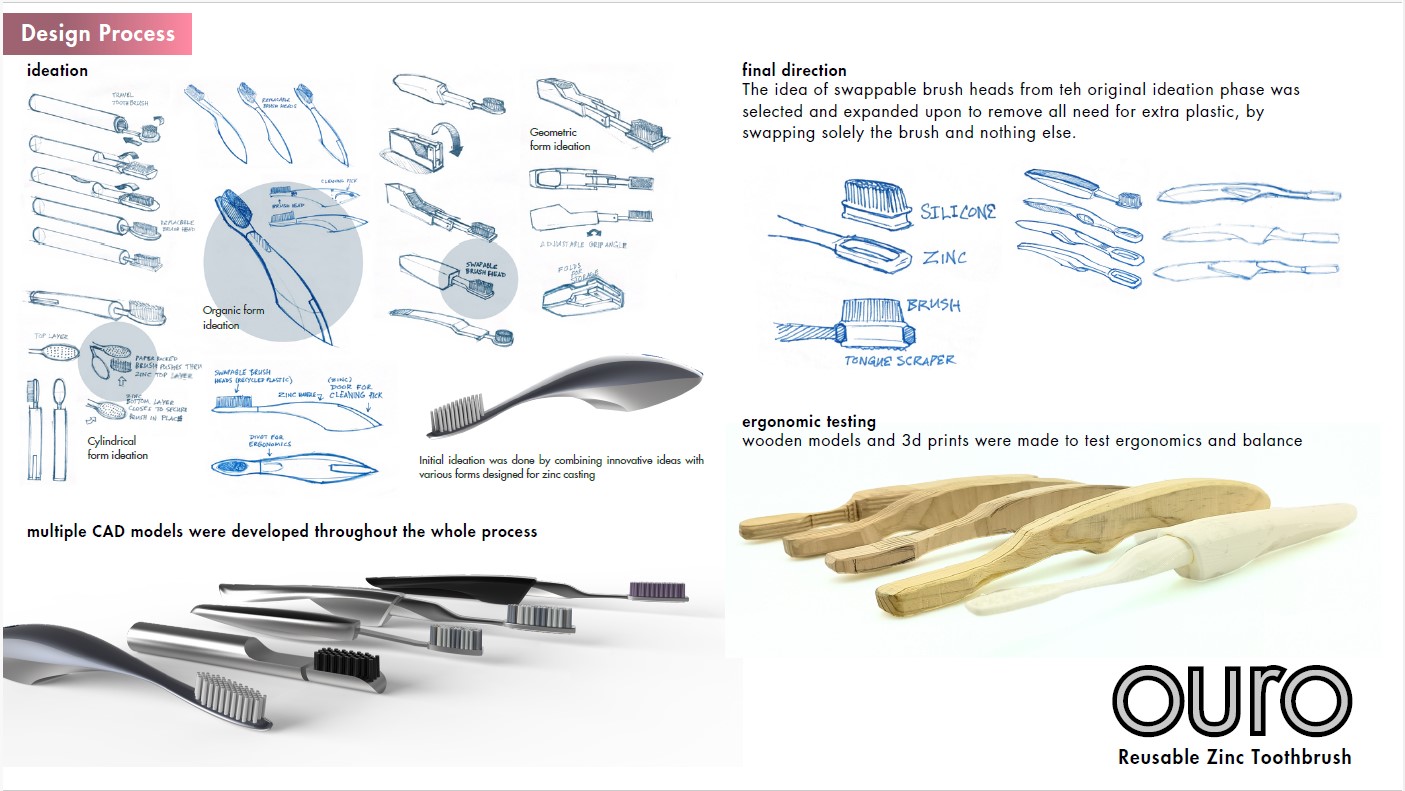

Title: OURU

Designer: Demitri Cortez Zehrung

School: Purdue University

Instructor: Steve Visser

Judges’ Comments:

- “Reusable zinc handle reduces waste”

- “Desirable colors for everyone “

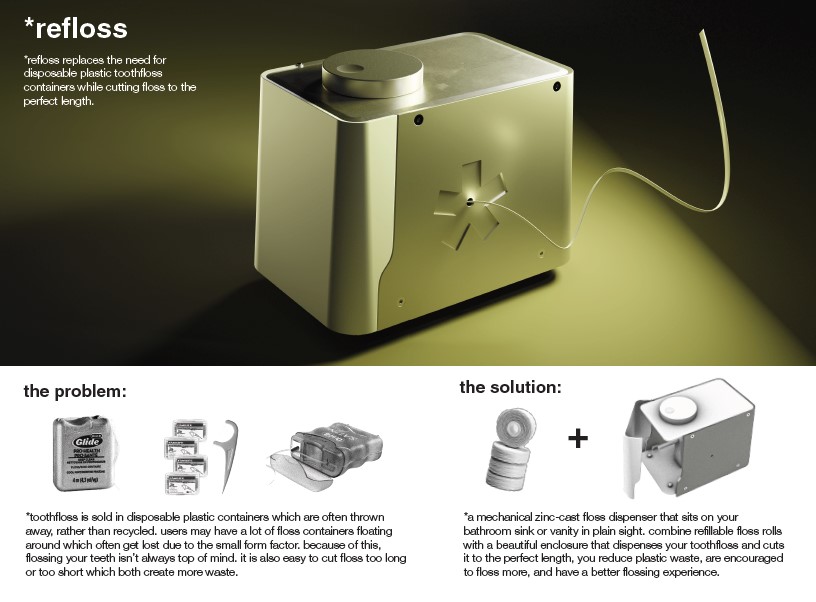

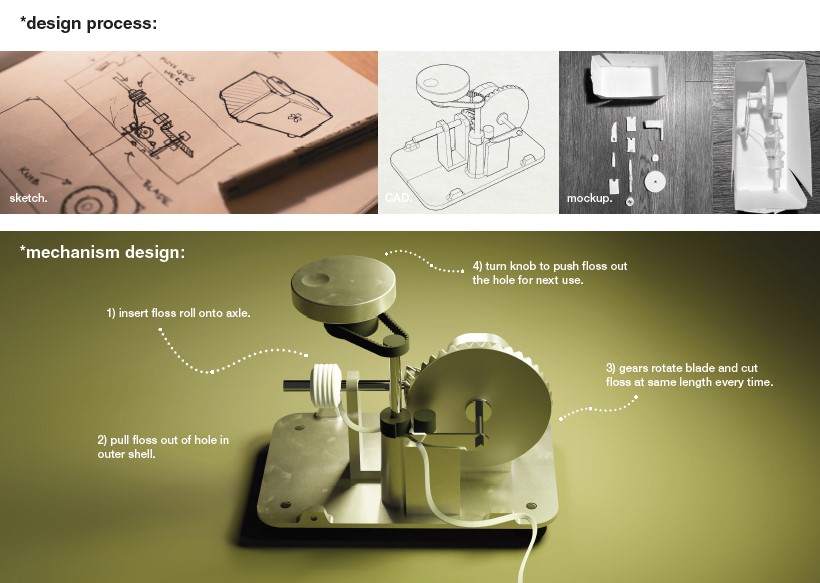

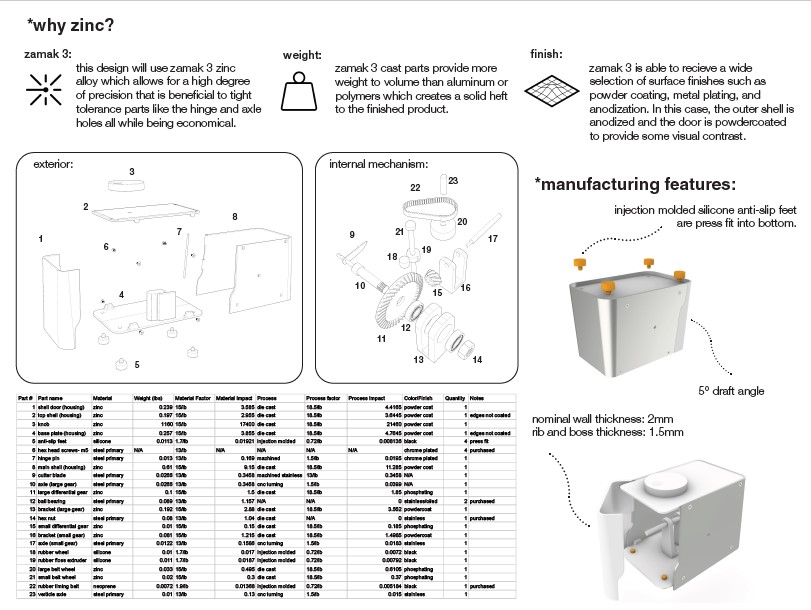

Title: Refloss

Designer: Miles Menely

School: University of Oregon

Instructor: Kiersten Muenchinger

Judges’ Comments:

-

“Visually appealing product can be displayed openly”

-

“Zinc allows mounting brackets to be cast in place”

ZINC CHALLENGE: 2022-2023

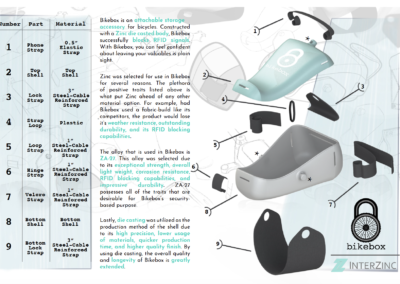

Active Transportation

Please note that winners are listed in no particular order

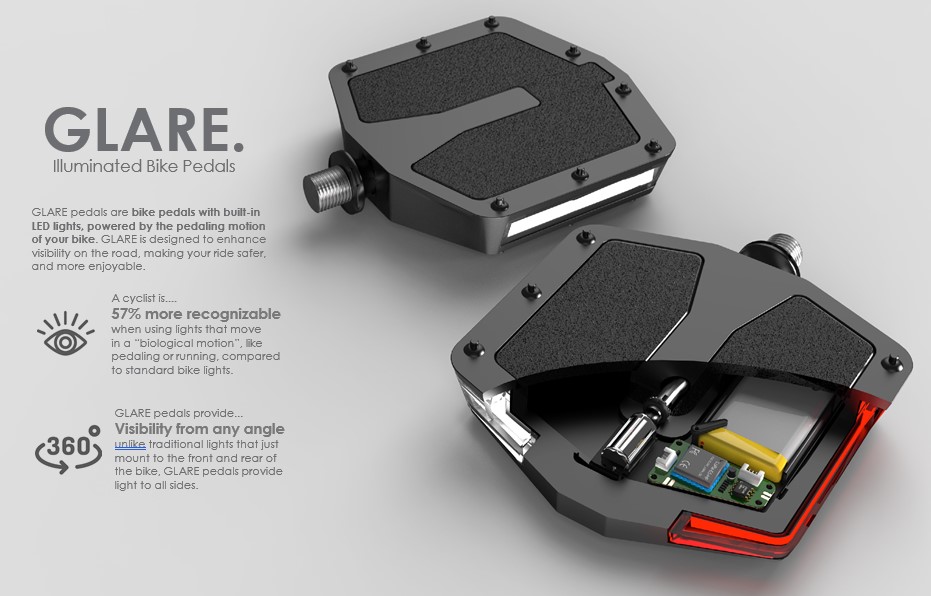

Title: Glare

Designer: Brady Hawks

School: Purdue University

Instructor: Abolfazi Ghaderi

Judges’ Comments:

“Excellent presentation of the design. The use of icons helps to convey the message of the written text.”

“Self-propelled and self-charging fits well with the contest theme.”

“The strength of zinc with thin wall casting will keep the pedals lightweight”

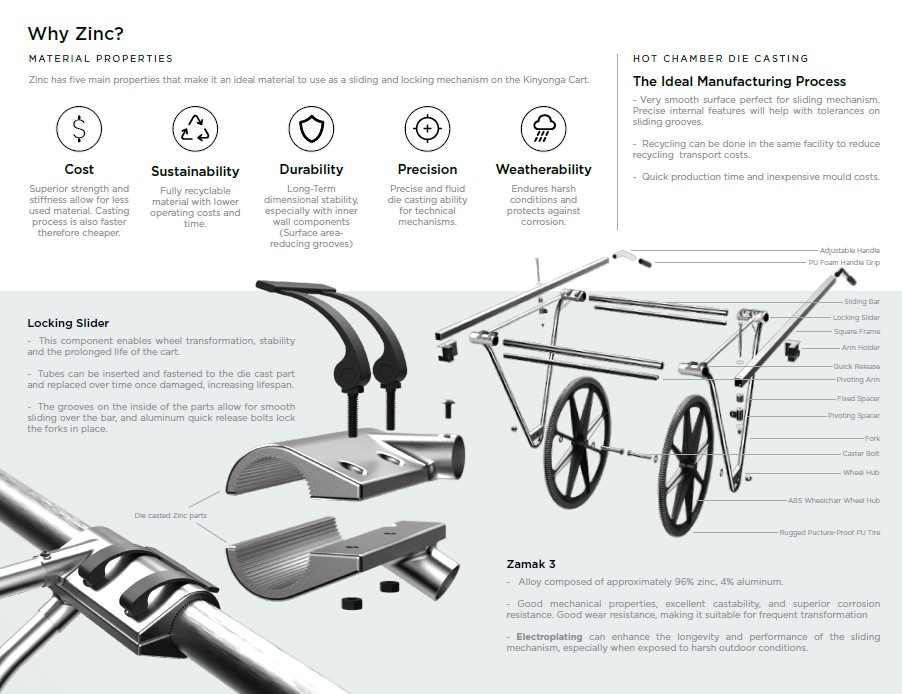

Title: Kinyonga Cart

Designer: Luke Wightman

School: Carleton University

Instructor: Stephen Field

Judges’ Comments:

“Interesting design idea to adjust the wheelbase for the different terrain.”

“The properties of zinc make it ideal for the application and the width of the clamp will add stability to the wheel supports.”

“Good alloy selection which could also be used for the pivoting arm holders providing the same strength, lubricity and corrosion resistance.”

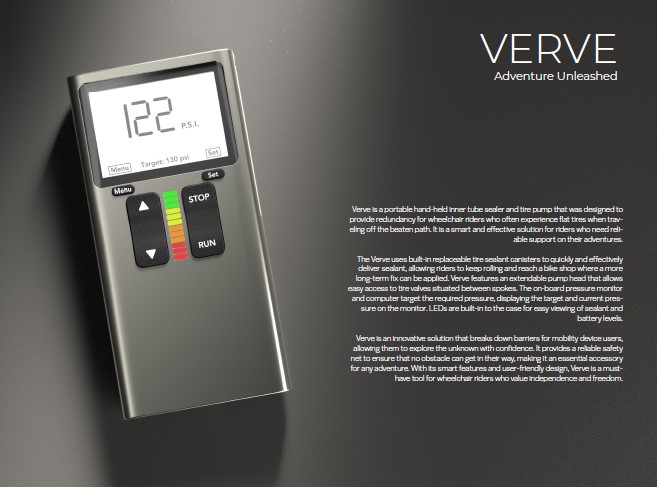

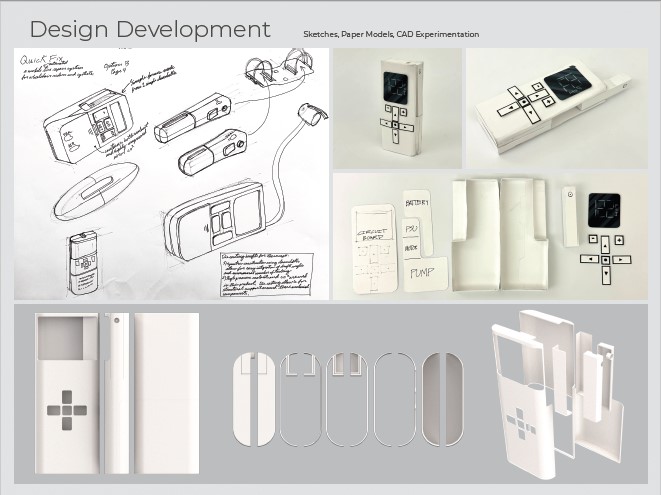

Title: Verve

Designer: Eli Mikiten

School: University of Oregon

Instructor: Tom Bonamici

Judges’ Comments:

“Zinc is used extensively for housings due to its high strength with good thermal and electrical conductivity. An excellent choice for a robust housing.”

“A good explanation for the alloy selection which is appropriate for the application.”

“Product could also be used in other market sectors.”

ZINC CHALLENGE: 2021-2022

Home Medical Devices

Please note that winners are listed in no particular order

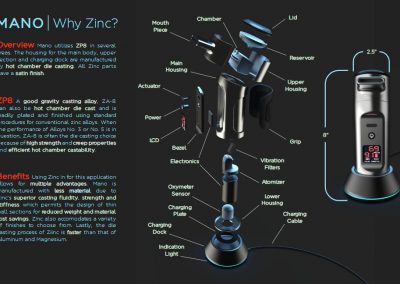

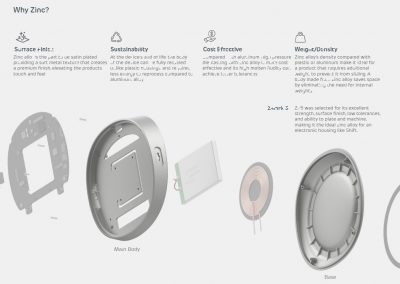

Title: Man O2 (Nebulizer & Oxymeter)

Designer: Kyle Alexander

School: CSULB

Instructor: Jose Rivera

Judges’ Comments:

- Professional layout of the presentation

- Good overview provided of zinc alloy properties

Title: Shift

Designer: Chris Lee

School: Carleton University

Instructor: Tim Haats

Judges’ Comments:

-

Impressive application of zinc’s physical properties to anchor the product

-

The student has a good understanding of the sustainability of using recycled materials, such as zinc

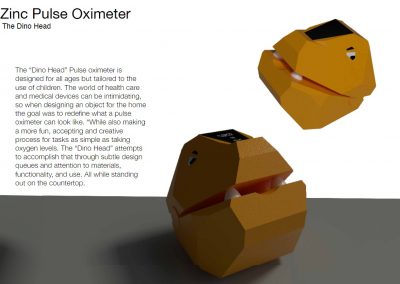

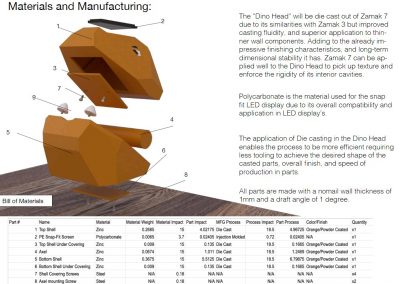

Title: Zinc Pulse Oximeter

Designer: Varney Varney

School: University of Oregon

Instructor: Kiersten Muenchinger

Judges’ Comments:

-

Very playful design, which exactly met the challenge for a visible home medical device

-

If used as a toy by kids, the strength of the zinc protects the internal components from any possible damage.

ZINC CHALLENGE: 2020-2021

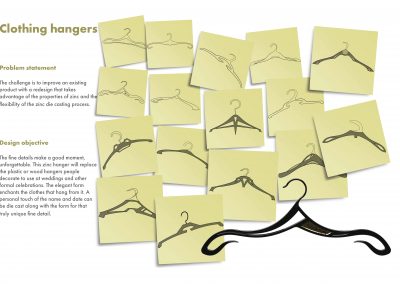

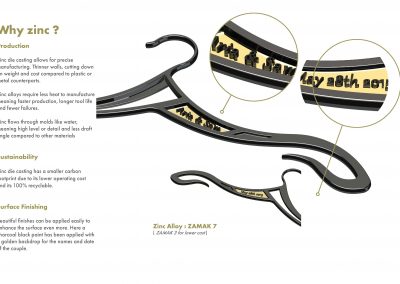

Product Redesign into Zinc

Please note that winners are listed in no particular order

- Good arguments why to switch from plastic to zinc (strength, ductility). High score for originality.

- Quite original, puts plastic into the penalty box!

- Good presentation, the renderings are nice and it is a good design. It also addresses a topic that is important in the industry ~ toxicity.

- Love the execution, attention to details and the non-toxic shout-out.

- I love the Sticky Note ideation ~ fantastic presentation.

- This is exactly what the competition was about: substitute other materials with zinc.

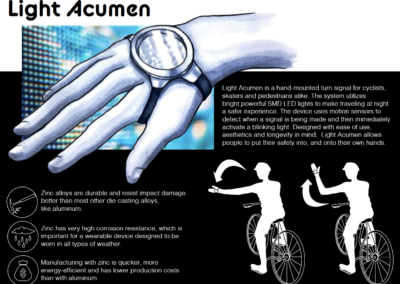

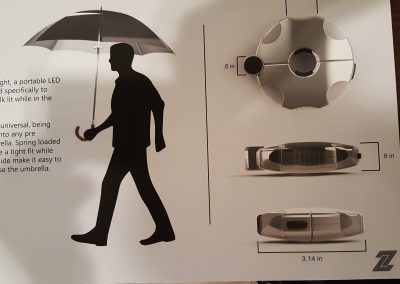

ZINC CHALLENGE: 2019-2020

Wearable Electronic Device

- “I really like the design. It is unique and original, and it’s clear the designer has thought through many of the challenges of wearing and using such an inventive product.”

- “The use of zinc (rigid material) makes sense in this wearable.”

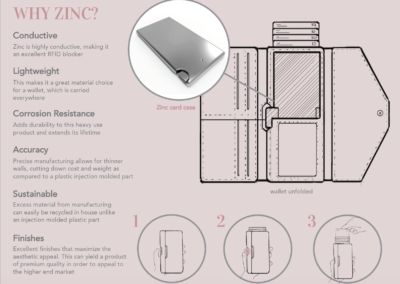

ZINC CHALLENGE: 2018-2019

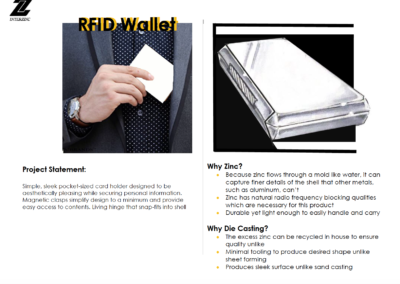

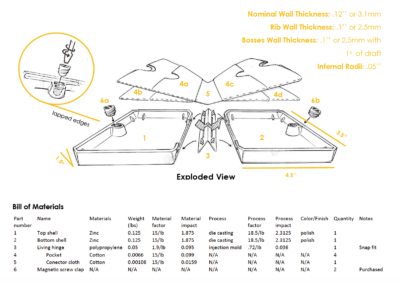

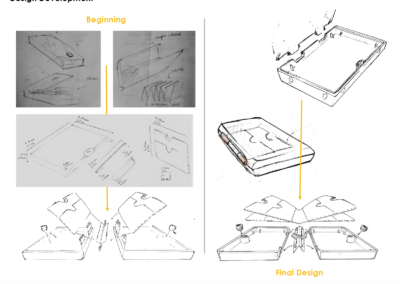

Radio Frequency Identification (RFID) – Shielding Capable Document Holder

- “The designer clearly understands how the properties of zinc contribute to the functionality for RFID shielding while providing thin walls and the superior surface finishing needed for a high end product.”

- “Utilizing zinc for the RFID wallet and the stylish clasps ties the design together.”

- “The designer complements the warmth of zinc with the use of natural materials on the inside of the wallet in this simple and functional product.”

- “‘Zinc came out ahead for castability when compared to other possible materials in this design.”

- “The designer’s choice of ZA-27 alloy provides high strength and RFID shielding for this application.”

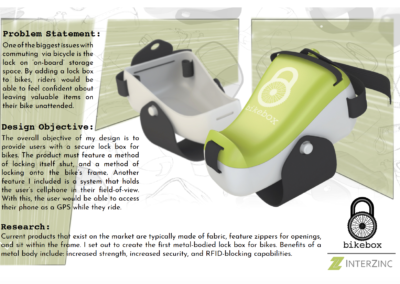

- “Cycling is growing in popularity and this design adds secure storage to the bike.”

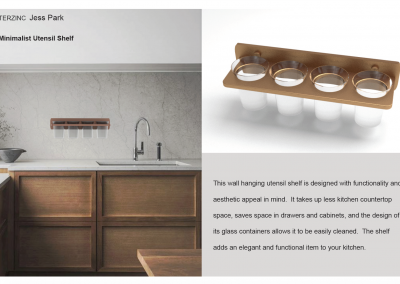

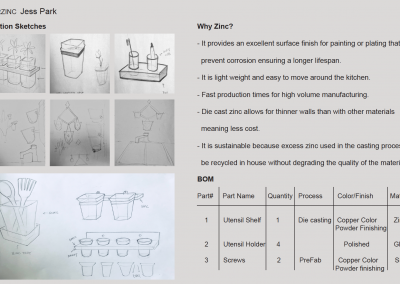

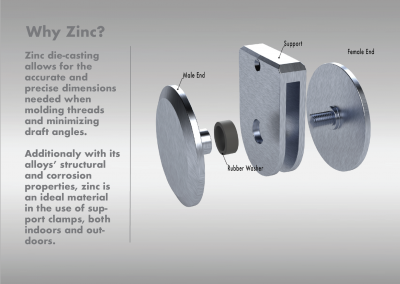

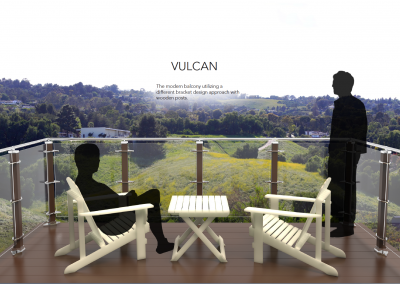

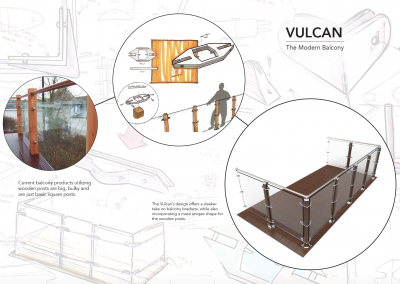

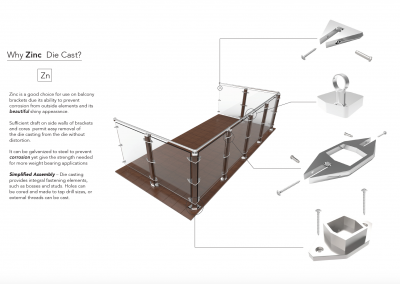

ZINC CHALLENGE: 2017-2018 – GLASS SUPPORT BRACKETS

- “I like the concept of this design. A very minimal design for utensils only, allowing for more drawer space for other kitchen products. The glass container can also be washed.”

- “The student makes use of zinc die casting’s high fluidity to make thinner walls as well as the use of ribs to help strengthen the part.”

-

“I like the interesting design for hanging glass giving increased flexibility with unlimited wire angles.”

-

“The student takes advantage of the ability to cast accurate dimensions and zinc’s corrosion resistance, which are both important for this application.”

-

“I like the use of various bracket designs for the different locations and functions on the balcony rail.”

-

“The student recognizes the ability of die cast zinc alloys to resist corrosion and still look shiny and beautiful.”

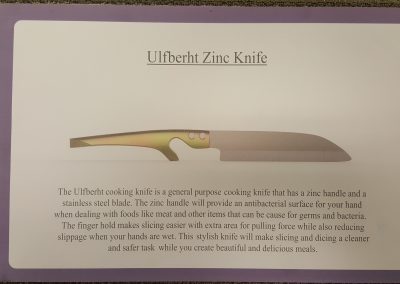

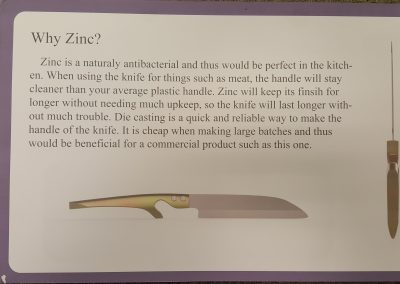

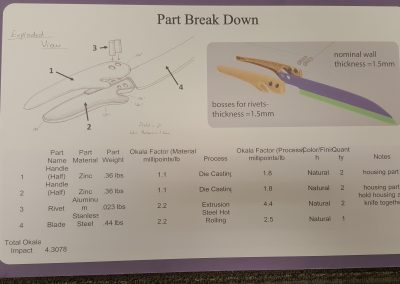

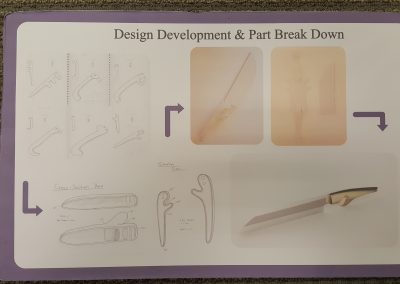

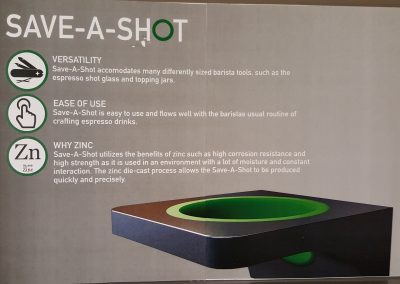

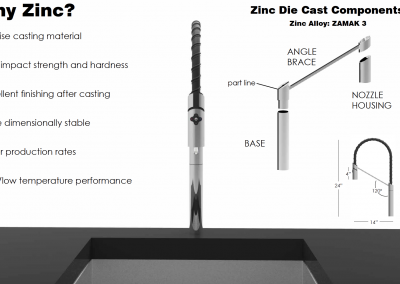

ZINC CHALLENGE: 2016-2017 – COMMERCIAL KITCHEN PRODUCTS

- ‘I liked the ergonomic look of this knife, and there may be an application for zinc in knife handles in general.’

- ‘Very well executed design process. Benefits of using zinc shown in good detail.’

- ‘Well executed design development with interesting historical reference.’

- ‘This is a good add-on product and clearly a good choice in zinc.’

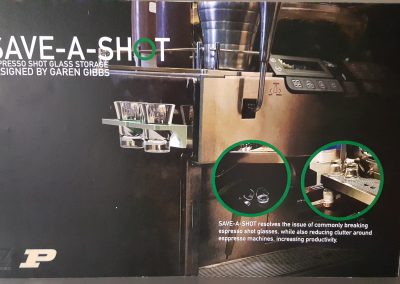

- ‘Excellent concept presentation. Imaginative solution to a barista’s problems.’

- ‘Simple aftermarket add-on product with wide market potential and easy integration.’

- ‘Although zinc is already used in faucets, I liked the novel idea of using electronic controls on the nozzle. The reason for using zinc was clearly presented.’

- ‘New imaginative approach to a one control faucet. Excellent execution of the design process.’

- ‘One hand control of all functionality of the faucet improves on existing designs.’