Casting Study: Quickclamp Air Prep System – IMI Norgren

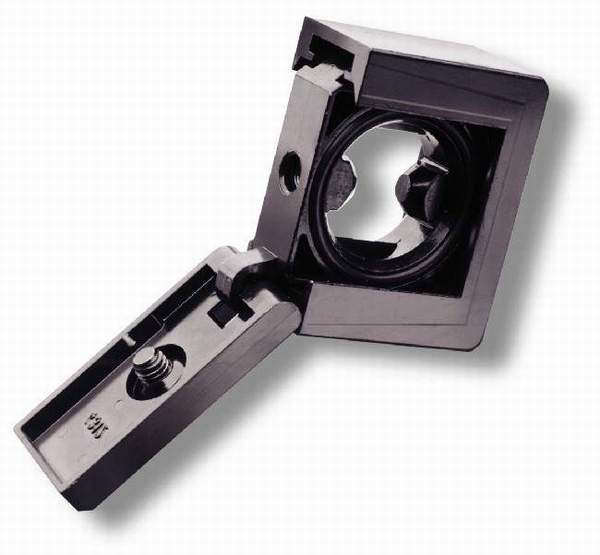

A newly designed air preparation system utilizes zinc die casting for the major components of the Quickclamp(TM) assembly (as well as the bodies, bowls, and accessory parts of the filters, regulators and lubricators). Die cast zinc provides greater strength than molded plastic for this application as well as lower production costs than aluminum die casting. This is because of its net shape characteristics and longer die life. Other critical factors that favor die cast zinc include its ability to maintain tight dimensional and flatness tolerances, low porosity, and good finish.

A newly designed air preparation system utilizes zinc die casting for the major components of the Quickclamp(TM) assembly (as well as the bodies, bowls, and accessory parts of the filters, regulators and lubricators). Die cast zinc provides greater strength than molded plastic for this application as well as lower production costs than aluminum die casting. This is because of its net shape characteristics and longer die life. Other critical factors that favor die cast zinc include its ability to maintain tight dimensional and flatness tolerances, low porosity, and good finish.