Casting Study: Motor Chassis

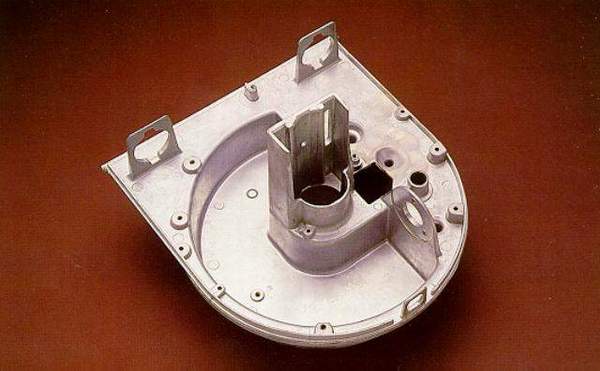

This chassis for a motor drive unit for an automatic opening roller door was made from several pressed metal parts prior to being designed as a zinc die casting. Die casting in zinc alloy 3 provided numerous benefits: 1.) Additional features such as pockets, the mounting flange and spigots for the gear train were able to be designed into the zinc casting. 2.) Post finishing operations were reduced. The castings need to be “linished” to remove excess metal on the parting line. Drilling of holes, forming operations, and fastening procedures that were previously needed were eliminated. 3.) The zinc castings are dimensionally stable, can readily achieve tight tolerances, and weigh less than the pressed metal counterpart.

This chassis for a motor drive unit for an automatic opening roller door was made from several pressed metal parts prior to being designed as a zinc die casting. Die casting in zinc alloy 3 provided numerous benefits: 1.) Additional features such as pockets, the mounting flange and spigots for the gear train were able to be designed into the zinc casting. 2.) Post finishing operations were reduced. The castings need to be “linished” to remove excess metal on the parting line. Drilling of holes, forming operations, and fastening procedures that were previously needed were eliminated. 3.) The zinc castings are dimensionally stable, can readily achieve tight tolerances, and weigh less than the pressed metal counterpart.