Casting Study: Computer Rear Cover

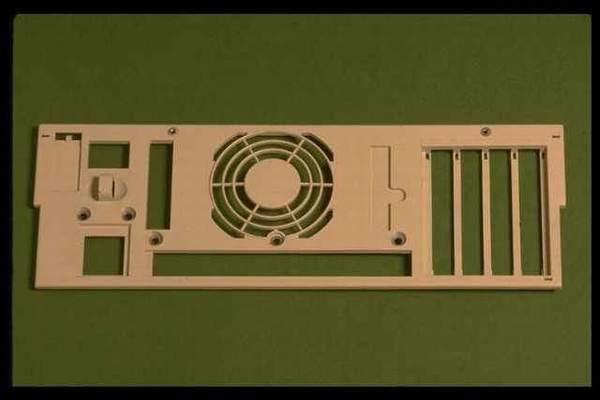

Micro-informatics are already an integral part of business and professional life. The will soon be present everywhere, including the home. What role do zinc alloys play? This back cover for a microcomputer illustrates how zinc die castings can simplify design and manufacturing while improving performance when compared with the combination of metal and plastics parts previously used. Making the part in ZA4U1G (equivalent to BS1004B) enabled it to be produced in a single operation with all the required characteristics: rigidity, dimensional accuracy, paintability, and—perhaps most importantly— improved electrical conductivity and electromagnetic shielding compared with the previous version. Furthermore, the foundry properties of the zinc alloy, such as fluidity and low shrinkage, enable a single part with all the necessary functions to be produced, whereas the previous version required a complex assembly operation involving several different parts.

Micro-informatics are already an integral part of business and professional life. The will soon be present everywhere, including the home. What role do zinc alloys play? This back cover for a microcomputer illustrates how zinc die castings can simplify design and manufacturing while improving performance when compared with the combination of metal and plastics parts previously used. Making the part in ZA4U1G (equivalent to BS1004B) enabled it to be produced in a single operation with all the required characteristics: rigidity, dimensional accuracy, paintability, and—perhaps most importantly— improved electrical conductivity and electromagnetic shielding compared with the previous version. Furthermore, the foundry properties of the zinc alloy, such as fluidity and low shrinkage, enable a single part with all the necessary functions to be produced, whereas the previous version required a complex assembly operation involving several different parts.