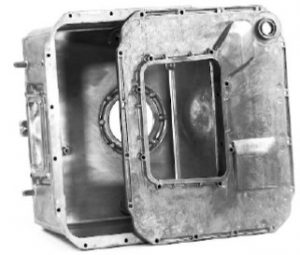

Casting Study: X-ray dental technology housing

The award-winning casting is characterized by a completely different zinc die-cast property than strength, filigree and thin walls. Due to its use as a component of an X-ray device, thick-walledness, tightness and also precision are in demand. In addition, the cast part has to meet the highest requirements for shielding against electromagnetic radiation. The cast housing is used in an X-ray device in dental medicine. It serves as a tank for a transformer oil with low viscosity, in which the X-ray tube is located. These requirements make the cast part, which initially appears voluminous and sluggish, into a highly complex component. The entire assembly also contains numerous add-on parts made of die-cast zinc, the fastening points of which must already be taken into account on the tank itself during the casting process. Because of the better properties for shielding radiation, no further sheathing, e.g. With lead, as would be the case with a different choice of material.

The jury emphasizes the special implementation of the requirements on the component. In addition to the challenge of casting a large-volume component in conjunction with a lot of mass, the jury sees the implementation of the requirements for precision, tight shape and position tolerances and the required impermeability to radiation as remarkable. The component shows in a special way the various possible solutions that can be implemented with zinc die-casting.