Casting Study: Wire Jointing Device

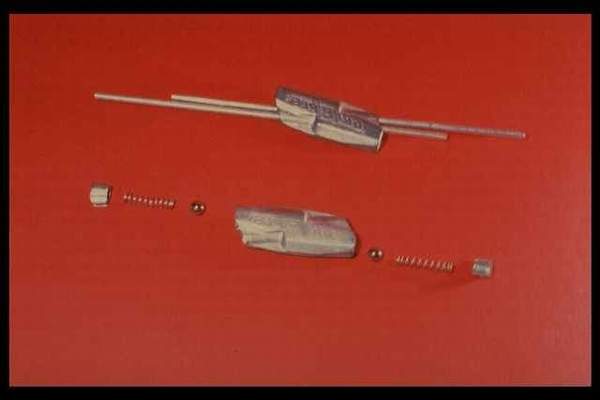

Estate Wire Ltd. established a massive potential market for a simple but effective wire jointing device. A specialized design consultancy service – Cheshire Engineering Ltd. – was commissioned to investigate the possibilities. After rejecting a number of alternatives, a very simple device involving only two springs and two ball bearings was designed. After much refinement, the “gripple” is the result. The search was then on for an economical means of manufacturing. The result was a device consisting of two very accurate zinc die castings which were riveted together. Further development has enabled the design to be further modified to use a single zinc alloy pressure die casting with two die cast retaining caps. The casting contains two close tolerance channels into which the wires to be joined are pushed into the device where they are retained by small steel ball bearings pressing the wire against the sides of the channels. The zinc alloy used is a specially hardened variation of ZA-8, developed so that the balls will not indent the zinc, but will bite sufficiently strongly into the steel wire to hold firmly. The effective grip is enhanced because the close tolerances on the diameter of the channel ensures full contact with the ball. Extremely close requirements on taper are also met. The “gripple” won the prestigious Prince of Wales award for Innovation and Production.

Estate Wire Ltd. established a massive potential market for a simple but effective wire jointing device. A specialized design consultancy service – Cheshire Engineering Ltd. – was commissioned to investigate the possibilities. After rejecting a number of alternatives, a very simple device involving only two springs and two ball bearings was designed. After much refinement, the “gripple” is the result. The search was then on for an economical means of manufacturing. The result was a device consisting of two very accurate zinc die castings which were riveted together. Further development has enabled the design to be further modified to use a single zinc alloy pressure die casting with two die cast retaining caps. The casting contains two close tolerance channels into which the wires to be joined are pushed into the device where they are retained by small steel ball bearings pressing the wire against the sides of the channels. The zinc alloy used is a specially hardened variation of ZA-8, developed so that the balls will not indent the zinc, but will bite sufficiently strongly into the steel wire to hold firmly. The effective grip is enhanced because the close tolerances on the diameter of the channel ensures full contact with the ball. Extremely close requirements on taper are also met. The “gripple” won the prestigious Prince of Wales award for Innovation and Production.