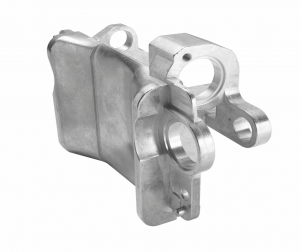

Casting Study: Support Unit for Drive

This product is a segment drive for imaging plate technology used in dentistry. A complex, modern, and advanced die casting enables precise and optimum shape design that is consistent with the mechanical properties of the die cast zinc alloy. In medical technology, die cast zinc has been used for many years; however, this area of application is not as well-known as others. The support unit has an exemplary design and is very sophisticated in mold making and casting technique. The intelligent component form achieves high dimensional stability. This particular product fully demonstrates the high design freedom of die cast zinc. The tool’s technical design allows high precision in all functional dimensions and delivers the required tolerances of the castings.

This product is a segment drive for imaging plate technology used in dentistry. A complex, modern, and advanced die casting enables precise and optimum shape design that is consistent with the mechanical properties of the die cast zinc alloy. In medical technology, die cast zinc has been used for many years; however, this area of application is not as well-known as others. The support unit has an exemplary design and is very sophisticated in mold making and casting technique. The intelligent component form achieves high dimensional stability. This particular product fully demonstrates the high design freedom of die cast zinc. The tool’s technical design allows high precision in all functional dimensions and delivers the required tolerances of the castings.

Fits and surface quality 9J6 to 16N7

Tolerances: 0.02 to 0.05 mm

Casting weight: 380g

Part weight: 292g

Cast on Frech DAW80F-RC

Finishing: Cr3 passivation.