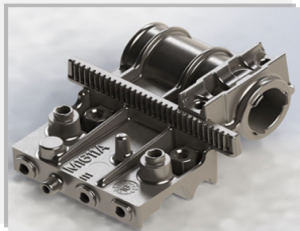

Casting Study: Subframe and Carriage

The three parts of this design form a subassembly that measures the thickness of ophthalmic lenses before edging. The frame ensures the palpate lever guidance in the ophthalmic glass machine tool. Then, the glass is machined with the contour note during the palpate operation.

The three parts of this design form a subassembly that measures the thickness of ophthalmic lenses before edging. The frame ensures the palpate lever guidance in the ophthalmic glass machine tool. Then, the glass is machined with the contour note during the palpate operation.

The frame put elements in place to palpate the glass. Its precision and its dimensional stability are essential for quality results.

- Part 1 (frame) weight: 390g

- Dimension: 155 x 78 x 92 mm

- Part 2 (lever) weight: 9g

- Dimension: 37 x 16 x 22 mm

- Part 3 (carriage) weight: 82g

- Dimension: 60 x 22 x 52 mm

- Alloy: ZP5

- Finishing: vibratory deburring, CNC machining, assembly

Reasons for choosing zinc alloy:

ZP5 was chosen over other materials for is lower cost, closer dimensional tolerances, easy machining, damping properties, and good surface finish.