Casting Study: Mobile Radio Antenna

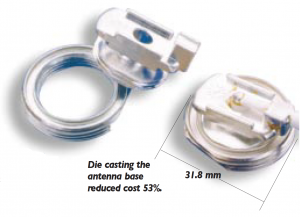

Zinc die casting was chosen to reduce cost of an antenna base for mobile radio equipment, which was originally a brass screw-machined part. Powder metallurgy was evaluated, but it couldn’t achieve the required undercuts without machining. Zamak 2 alloy was specified to provide the required strength, corrosion resistance, processability, and thermal conductivity. The decision was made to die cast the nut as well as the bushing doubled the savings of the whole assembly, reducing costs 53% over the brass component. In addition, die casting eliminated a separate soldering terminal by making it an integral part of the bushing. This reduced the part count and eliminated an inventory handling step as well as a swaging operation. Assembly time reduced 40% as well. Consistency of the die cast parts enabled component handling automation during assembly for further cost reductions.

Zinc die casting was chosen to reduce cost of an antenna base for mobile radio equipment, which was originally a brass screw-machined part. Powder metallurgy was evaluated, but it couldn’t achieve the required undercuts without machining. Zamak 2 alloy was specified to provide the required strength, corrosion resistance, processability, and thermal conductivity. The decision was made to die cast the nut as well as the bushing doubled the savings of the whole assembly, reducing costs 53% over the brass component. In addition, die casting eliminated a separate soldering terminal by making it an integral part of the bushing. This reduced the part count and eliminated an inventory handling step as well as a swaging operation. Assembly time reduced 40% as well. Consistency of the die cast parts enabled component handling automation during assembly for further cost reductions.