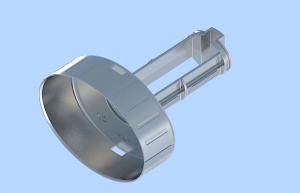

Casting Study: High Tension Cage

This part is a device component warranting the operators security during intervention on high-tension lines. The reasons behind choosing zinc alloy include the product’s complex tool design, the combination of thin wall casting and rigidity, and the dimensional requirements, e.g. internal and external tolerances.

This part is a device component warranting the operators security during intervention on high-tension lines. The reasons behind choosing zinc alloy include the product’s complex tool design, the combination of thin wall casting and rigidity, and the dimensional requirements, e.g. internal and external tolerances.

The part weighs 148g and measures 79 x 79 x 94 mm. The alloy used was ZP5, and the finishing process involved cutting, shot blasting, and threading, finished with a white zinc coating.