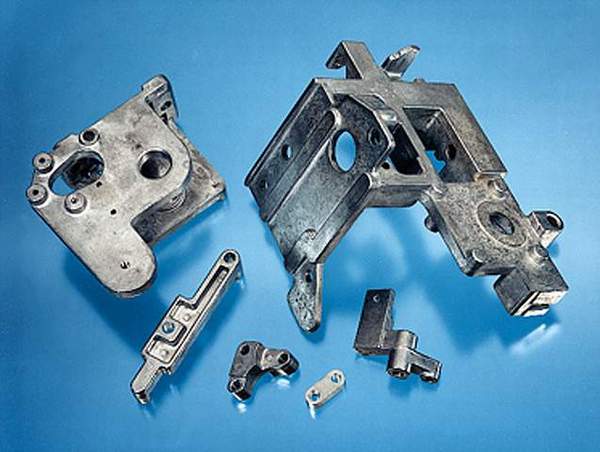

Casting Study: Frame Housing and Five Additional Mechanical Components

Key material requirements for the office bundling machine are hardness and strength, the ability to hold good tolerances, and lubricity. ZA-27 was selected as the die casting material because of its hardness, strength, dimensional stability, and natural lubricity. By designing the frame housing as a die casting, 27 separate parts were combined into a single casting. Receptacles for pressed-in bearings for ground-and-polished shafts needed only slight finish-reaming before bearing insertion. The bundling mechanism incorporates both rotary and sliding motion. While some motions are intended to be lubricated through oil ports, the inherent lubricity of ZA-27 provides a margin of protection against user neglect, adequate by itself to support a particular motion, or both. Using ZA-27 also decreased weight, permitting the unit to be handled and shipped easily.

Key material requirements for the office bundling machine are hardness and strength, the ability to hold good tolerances, and lubricity. ZA-27 was selected as the die casting material because of its hardness, strength, dimensional stability, and natural lubricity. By designing the frame housing as a die casting, 27 separate parts were combined into a single casting. Receptacles for pressed-in bearings for ground-and-polished shafts needed only slight finish-reaming before bearing insertion. The bundling mechanism incorporates both rotary and sliding motion. While some motions are intended to be lubricated through oil ports, the inherent lubricity of ZA-27 provides a margin of protection against user neglect, adequate by itself to support a particular motion, or both. Using ZA-27 also decreased weight, permitting the unit to be handled and shipped easily.