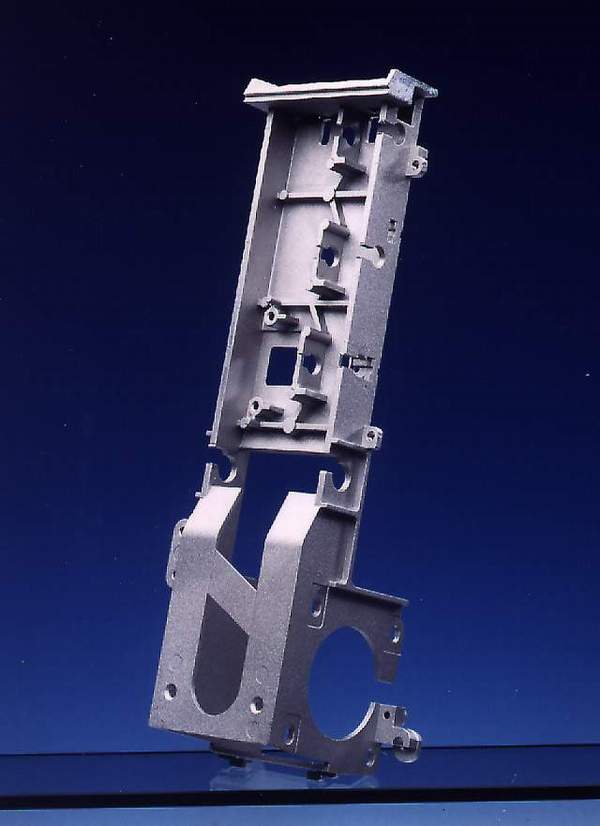

Casting Study: Frame Cover

The high dimensional tolerances possible with zinc die casting permitted precise and reliable seating of 6 bushings, diameter 8 mm/0.31 inches, with a diametral tolerance of ± 0.015 mm without additional machining. The complex shapes achievable in zinc die casting also permitted integration of various functions (motor bracket, axle housings that provide the motion for input and output of the ticket, positioning of the detection cell far more reliably than press formed steel sheet which reduced assembly cost. The zinc die casting provided electromagnetic shielding that was not possible in plastic, and a much more rigid part compared to the assembly of multiple parts that would be required in aluminum or steel.

The high dimensional tolerances possible with zinc die casting permitted precise and reliable seating of 6 bushings, diameter 8 mm/0.31 inches, with a diametral tolerance of ± 0.015 mm without additional machining. The complex shapes achievable in zinc die casting also permitted integration of various functions (motor bracket, axle housings that provide the motion for input and output of the ticket, positioning of the detection cell far more reliably than press formed steel sheet which reduced assembly cost. The zinc die casting provided electromagnetic shielding that was not possible in plastic, and a much more rigid part compared to the assembly of multiple parts that would be required in aluminum or steel.