Casting Study: Ezi – Fill Fuel Dispenser

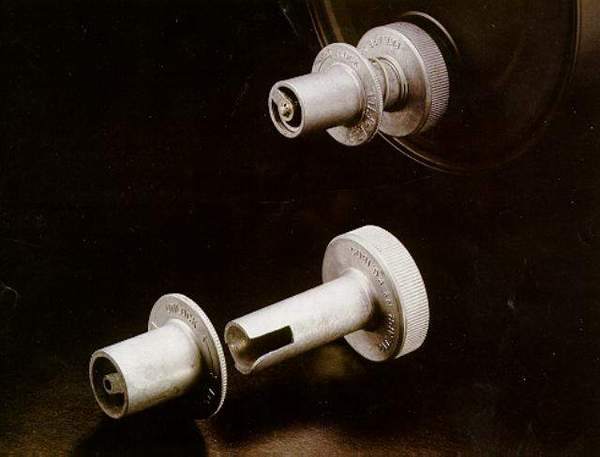

Its strength, tolerance for accurate detailing, non-corrosive properties compared to aluminium, and production speeds (faster than plastic) made die cast zinc the obvious solution when it came to the manufacture of Unicast’s “Ezi – Fill” fuel dispenser. Manufactured in Zinc Alloy 3, the two pressure die cast pieces demanded fine tolerances, strength and rigidity, and an ability to withstand the corrosiveness of fuels in addition to speed in production to reduce final cost. With a thread already cast-in, the dispenser is finished by turning the thread and inserting washers and seals to form a child and leak proof product.

Its strength, tolerance for accurate detailing, non-corrosive properties compared to aluminium, and production speeds (faster than plastic) made die cast zinc the obvious solution when it came to the manufacture of Unicast’s “Ezi – Fill” fuel dispenser. Manufactured in Zinc Alloy 3, the two pressure die cast pieces demanded fine tolerances, strength and rigidity, and an ability to withstand the corrosiveness of fuels in addition to speed in production to reduce final cost. With a thread already cast-in, the dispenser is finished by turning the thread and inserting washers and seals to form a child and leak proof product.