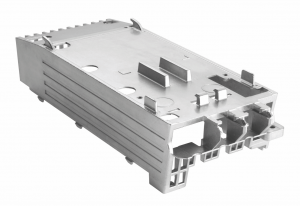

Casting Study: Electronics Housing

This casting is a housing for the most demanding industrial electronics. To avoid short circuits, it needs to be free of residual particles. To save costs for post-processing and cleaning steps, a net-shape mold concept was developed. Moreover, the housing is a complex cast part with a high level of difficulty; this requires high tolerance and accuracy (near-net-shape). The length of the flow paths in relation to the wall thickness is a particular challenge.

Assembly: Cast on 200ton machine, remove gate and overflows, CNC machining, grinding, glue the parts with rubber gasket, gluing the EMC seal.

Part size: 190 x 72 x 55 mm

Weight: 420g

Wall thickness: 1.5mm.