Casting Study: Copper Cable Connectors

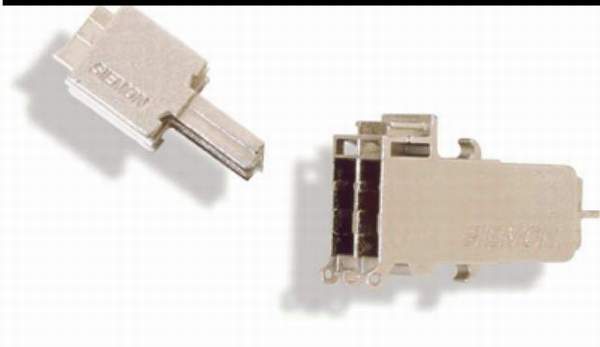

Zinc die casting was chosen to produce this new generation of cable connectors. Critical standards that were met include wall strength to assure durability and to withstand bulk processing and proper matching of draft allowances on the internal surfaces for smooth mating and secure electrical contact. The resulting die cast connector provides 360-degree electronic shielding of each pair and gives 4-, 2-, and 1-pair connection options. The exterior connector surfaces are textured for an attractive, uniform, matte finish. The castings are produced with tight dimensional tolerances that yield a net shape that is flash-free.

Zinc die casting was chosen to produce this new generation of cable connectors. Critical standards that were met include wall strength to assure durability and to withstand bulk processing and proper matching of draft allowances on the internal surfaces for smooth mating and secure electrical contact. The resulting die cast connector provides 360-degree electronic shielding of each pair and gives 4-, 2-, and 1-pair connection options. The exterior connector surfaces are textured for an attractive, uniform, matte finish. The castings are produced with tight dimensional tolerances that yield a net shape that is flash-free.