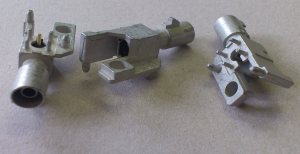

Casting Study: Connector for Radio AM/FM Signal

The part has the following attributes: One of this part’s highlights is its functionality—it allows one single part in Zamak for electrical connection (interface) and mechanical (coding + retention). It also has a connector function, which allows for the transmission of RF, AM, and FM signals. There is a reflow soldering assembly process involved in the part’s realization, which allows a profile temperature up to 260°C.

The part has the following attributes: One of this part’s highlights is its functionality—it allows one single part in Zamak for electrical connection (interface) and mechanical (coding + retention). It also has a connector function, which allows for the transmission of RF, AM, and FM signals. There is a reflow soldering assembly process involved in the part’s realization, which allows a profile temperature up to 260°C.

Zinc alloy was chosen for several reasons: fluidity for casting, allowing complex form and thin wall to be obtained and ensuring high dimensional precision for a perfect assembly; ability to be coated, as this part is plated with Cu8 Ni2 Sn4 in a satin finish; ability for crimping assembly; recyclability for electronics application; high capacity for high production quantities (80,000 parts/month); competitive costs compared to other types of manufacturing. The product comes in a reel for robotized mounting on the electronic card, as packaging was adapted to the customer’s assembly process.