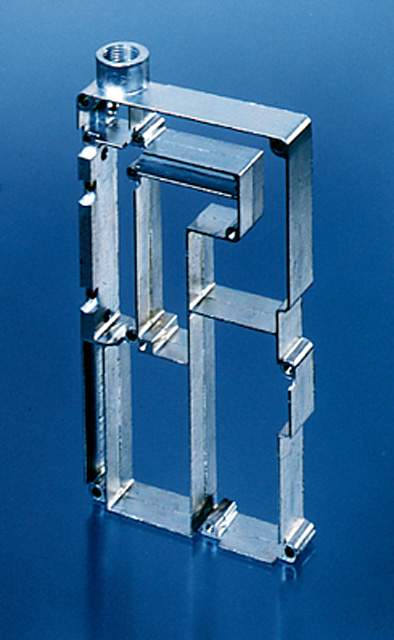

Casting Study: Chassis, Shield and Synthesizer Housing

The Ericsson GE Mobile Communicat ions’ M-PA personal radio incorporates three Zamak 3 die castings: the chassis or circuit board frame, the chassis shield, and the synthesizer housing. These castings combine to provide strength and rigidity demanded for dependable radio performance. The circuit board frame compartmentalizes and isolates the various electronic transmitter components providing EMI/RFI shielding. To maximize space and minimize weight, the chassis is cast with very thin walls, 0.032 in. maximum at the parting line and 0.024 in. at the taper. The synthesizer housing encloses the voice oscillators, providing complete EMI/RFI shielding. A zinc casting was chosen because of zinc’s physical properties and the cost advantage over stamping, deep drawing, and aluminium casting. The third zinc casting is the chassis shield. This 0.031 in. thick component provides a mounting for the radio speaker and shields the internal electronics from magnetic interference.

ions’ M-PA personal radio incorporates three Zamak 3 die castings: the chassis or circuit board frame, the chassis shield, and the synthesizer housing. These castings combine to provide strength and rigidity demanded for dependable radio performance. The circuit board frame compartmentalizes and isolates the various electronic transmitter components providing EMI/RFI shielding. To maximize space and minimize weight, the chassis is cast with very thin walls, 0.032 in. maximum at the parting line and 0.024 in. at the taper. The synthesizer housing encloses the voice oscillators, providing complete EMI/RFI shielding. A zinc casting was chosen because of zinc’s physical properties and the cost advantage over stamping, deep drawing, and aluminium casting. The third zinc casting is the chassis shield. This 0.031 in. thick component provides a mounting for the radio speaker and shields the internal electronics from magnetic interference.

.