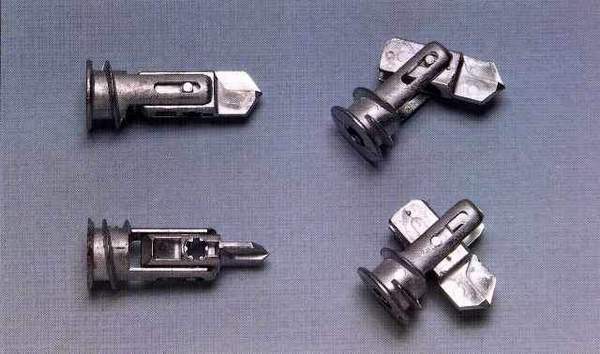

Casting Study: Attachment Insert

This high performance self-drilling insert for plaster board (partition, lining, ceiling) is delivered with a self-tapping screw, forming two parts (cap and toggle) produced in a single casting operation. The parts are connected by four 0.9 mm diameter pins, which separate during installation and remain nested one inside the other, the toggle being able to translate and rotate by two 2 mm diameter pivots. Zamak was chosen for several reasons. It has high fluidity which allows for complex and precise tooling, and its excellent mechanical properties allow the use of self-tapping screws. It also has a very good natural corrosion resistance so that it can be used without surface treatment, while guaranteeing there will be no rust stains. Pressure die casting is a particularly economic technique for this type of large series production. Part supplied by Sigre.

This high performance self-drilling insert for plaster board (partition, lining, ceiling) is delivered with a self-tapping screw, forming two parts (cap and toggle) produced in a single casting operation. The parts are connected by four 0.9 mm diameter pins, which separate during installation and remain nested one inside the other, the toggle being able to translate and rotate by two 2 mm diameter pivots. Zamak was chosen for several reasons. It has high fluidity which allows for complex and precise tooling, and its excellent mechanical properties allow the use of self-tapping screws. It also has a very good natural corrosion resistance so that it can be used without surface treatment, while guaranteeing there will be no rust stains. Pressure die casting is a particularly economic technique for this type of large series production. Part supplied by Sigre.