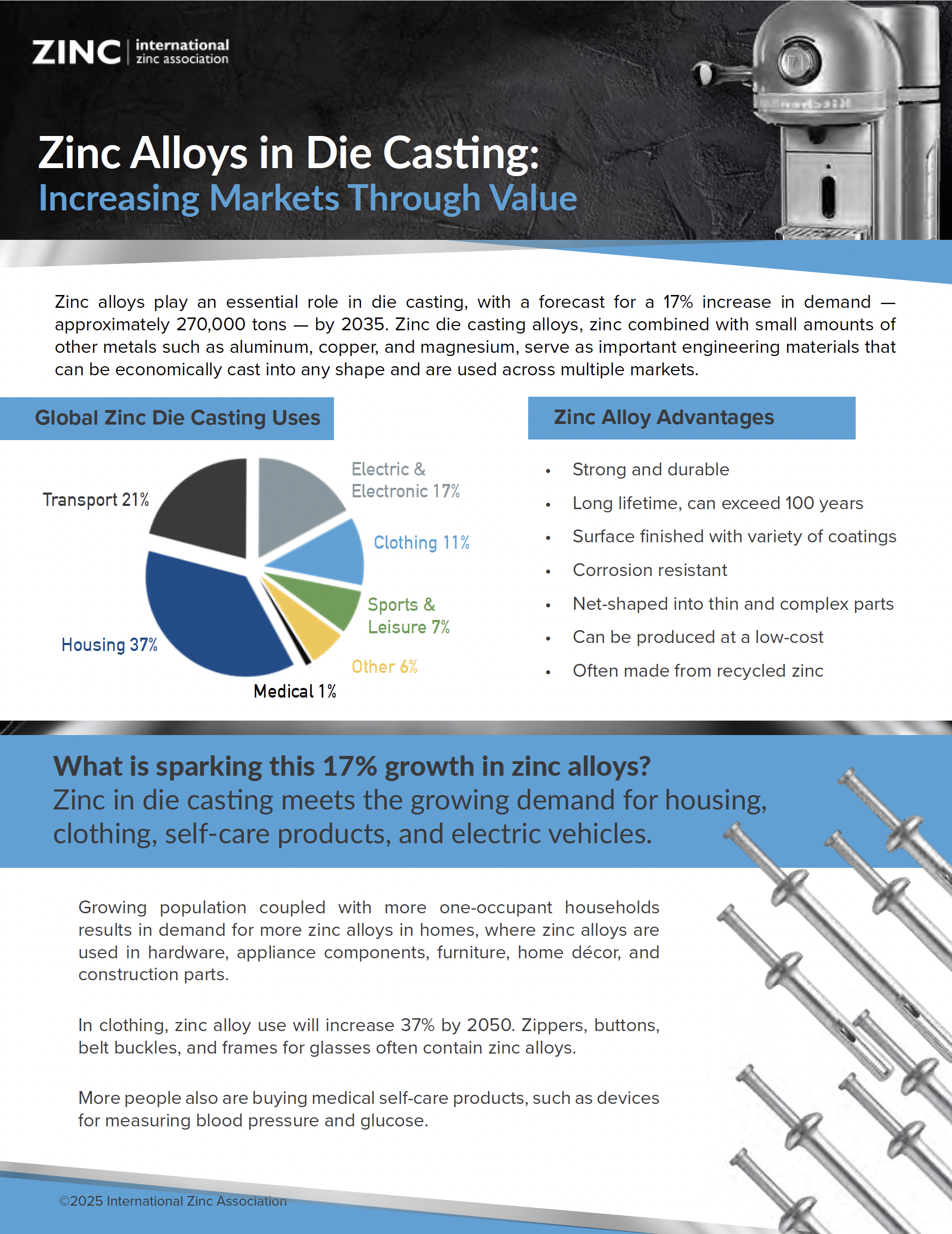

Zinc Alloys in Die Casting: Increasing Markets Through Value

Zinc alloys play an essential role in die casting, with a forecast for a 17% increase in demand – approximately 270,000 tons – by 2035. Zinc die casting alloys, zinc combined with small amounts of other metals such as aluminum, copper, and magnesium, serve as important engineering materials that can be economically cast into any shape and are used across multiple markets.

Engineering in Zinc, Today's Answer

IZA is dedicated to increasing awareness of zinc casting alloys among engineers, designers and specifiers through technology transfer, technical services and designer education programs. View our latest brochure for an overview of the benefits and properties of zinc casting alloys.

Ultra Thin Zinc Die Casting Alloys

This publication presents characteristics of the High Fluidity (HF) Alloy based on the traditional Zamak composition as well as the earlier developed copper-rich alloy marketed under the names of Superloy and GDSL. Both allow for thin section castings and have new market potential.

Finishes for Zinc Die Castings

This publication provides the performance results of a series of new surface finishes using best practice green technology that were tested in two categories – corrosion protection and aesthetic retention and compares them to the results of an earlier study of traditional surface finishes.