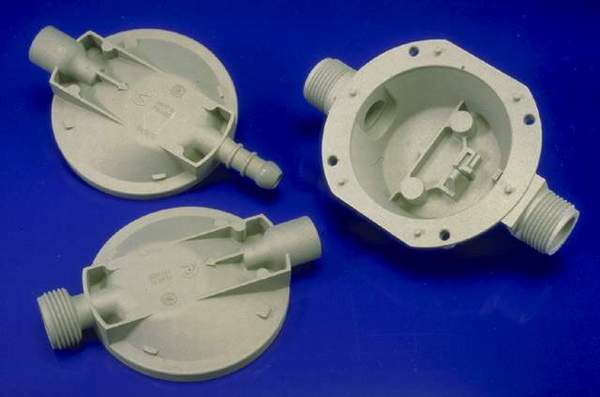

Casting Study: Cup and Cover of Gas Expander

Zinc die cast household gas expanders are often unnoticed but have performed reliably for more than 40 years, even as requirements have become stricter. Zinc castings allow meeting of the pressure tightness specification, which is that the assembly is pressure tight under 300 mbar at 5 bars. Zinc alloys shrink much less than aluminum, making pressure tightness easer to achieve. Also zinc die castings permit a die life 5 times longer compared to aluminum. Alignment of the moving rods and levers can be fixed by crimping, a well-developed process for assembling zinc die castings

Zinc die cast household gas expanders are often unnoticed but have performed reliably for more than 40 years, even as requirements have become stricter. Zinc castings allow meeting of the pressure tightness specification, which is that the assembly is pressure tight under 300 mbar at 5 bars. Zinc alloys shrink much less than aluminum, making pressure tightness easer to achieve. Also zinc die castings permit a die life 5 times longer compared to aluminum. Alignment of the moving rods and levers can be fixed by crimping, a well-developed process for assembling zinc die castings