Casting Study: Base Plate and Shaft Support

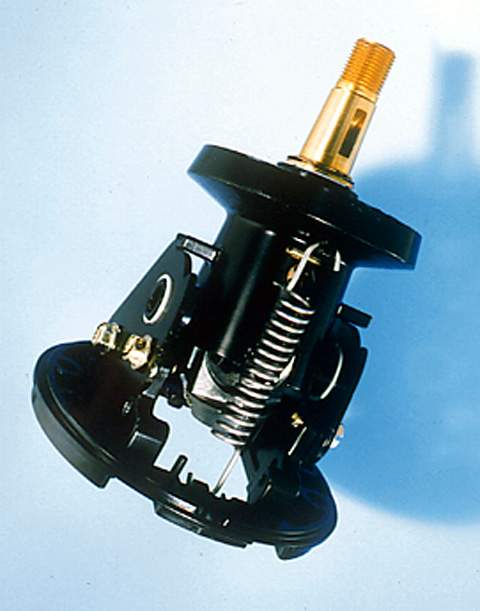

While competitive versions rely on plastic, the Morse Controls high-end pleasure boat mechanical steering control utilises ZA-8 alloy die casting for the Command 290 base plate and shaft support. ZA-8 alloy was chosen for two reasons: superior mechanical properties and its ability to be hot chamber die cast for tight tolerances and dimensional accuracy. An additional benefit of ZA-8 is superior wear properties for the shaft support’s three bearing surfaces. For casting efficiency and part functionality, the base plate is designed so all holes on the horizontal plane are cast-in. Only the holes on the vertical plane are machined. A spring tab is also cast onto the base. The shaft support is cast completely to shape. The only secondary operation performed is the reaming of the center hole. Radius guides and adjustment teeth are cast into the shaft support, and a second spring tab is incorporated into the base of the support to hold the other end of the 26 lb./in.-rated spring. Both the base plate and the shaft support are E-coated.

While competitive versions rely on plastic, the Morse Controls high-end pleasure boat mechanical steering control utilises ZA-8 alloy die casting for the Command 290 base plate and shaft support. ZA-8 alloy was chosen for two reasons: superior mechanical properties and its ability to be hot chamber die cast for tight tolerances and dimensional accuracy. An additional benefit of ZA-8 is superior wear properties for the shaft support’s three bearing surfaces. For casting efficiency and part functionality, the base plate is designed so all holes on the horizontal plane are cast-in. Only the holes on the vertical plane are machined. A spring tab is also cast onto the base. The shaft support is cast completely to shape. The only secondary operation performed is the reaming of the center hole. Radius guides and adjustment teeth are cast into the shaft support, and a second spring tab is incorporated into the base of the support to hold the other end of the 26 lb./in.-rated spring. Both the base plate and the shaft support are E-coated.